Published on: December 9, 2023

Written by Jonas Frank / Fact-checked by Nova Scarlett

Water should be added to a forklift battery after charging. This is the optimal time for maintenance.

Maintaining a forklift battery involves regular water top-ups, which are essential for its longevity and performance. The type of water used is critical; distilled water is the recommended choice for forklift batteries. This is because it doesn’t contain minerals that could harm the battery cells. When adding water, it’s vital to follow the forklift battery top-up procedure, which ensures safety and efficiency. The procedure typically includes checking the water level and filling each cell to the correct level, avoiding overfilling.

The frequency of adding water to a forklift battery varies based on usage but doing it periodically is key. A common question is whether to add water before or after charging. The answer is always after charging, as this helps in maintaining the correct electrolyte level and prevents overflow during charging. Neglecting to add water can lead to a decrease in battery life and performance. In severe cases, a forklift battery can run out of water, leading to cell damage and reduced efficiency.

Adhering to safety standards, such as those outlined by OSHA, is essential when handling forklift batteries. This includes proper spacing of the forks when picking up a load, as well as following the correct procedure for water addition. For more detailed information on maintaining your forklift battery and ensuring its optimal performance, read the detailed article below.

Optimal Timing for Forklift Battery Water Refills

The Ideal Time for Water Addition in Forklift Batteries

Understanding the Charging Cycle

Let’s talk about your forklift battery’s charging cycle. It’s like giving your battery a meal; you don’t want to overfeed it or leave it hungry. The best time to add water is after the charging cycle. Why? Because during charging, the water in the battery heats up and expands. If you add water before charging, there’s a risk of overflow, which is not only messy but can also harm the battery’s cells. So, remember, patience is key! Wait until the charging is done, then quench your battery’s thirst.

Effects of Water Levels on Battery Health

Maintaining the right water level in your forklift battery is like hitting the sweet spot in a game. Too little water, and the battery’s internal plates can get damaged. Too much water, and you might face spillage, leading to corrosion and other issues. It’s all about balance. Keeping the water level just right ensures your battery lives a long and healthy life, powering your forklift efficiently.

Choosing the Right Water for Your Forklift Battery

Distilled vs. Tap Water

Now, let’s chat about the type of water your forklift battery needs. Imagine using tap water in your iron; you’ll end up with mineral build-ups, right? The same goes for your battery. Distilled water is the way to go. It’s free from minerals and impurities that can clog up and harm the battery cells. So, stick to distilled water to keep your battery running smoothly.

Impact of Water Quality on Battery Longevity

| Water Type | Mineral Content | Effect on Battery Life |

| Distilled | Low | Extends battery life |

| Tap | High | Reduces battery life |

This table shows why distilled water is your battery’s best friend. It’s all about keeping those harmful minerals away from the delicate internal components of your battery. By using distilled water, you’re essentially giving your battery a longer, healthier life.

Step-by-Step Guide to Adding Water to Forklift Batteries

Safety Precautions

Safety first, folks! When you’re about to add water to your forklift battery, gear up with protective eyewear and gloves. Batteries contain acids, and you definitely don’t want that stuff on your skin or in your eyes. Also, make sure you’re in a well-ventilated area. Safety isn’t just a suggestion; it’s a must!

Detailed Procedure for Water Addition

Alright, let’s get down to business. Adding water to your forklift battery isn’t rocket science, but it does need some care. Start by removing the battery caps. Then, take a peek inside. You’ll see some markers indicating the maximum water level. Use a funnel or a watering gun to fill each cell up to that mark, but not beyond. Overfilling is a no-no. Once you’re done, replace the caps, and you’re all set!

Frequency of Water Top-Ups in Forklift Batteries

Factors Influencing Water Consumption

Your forklift battery’s thirst depends on a few things. How often you use it, the temperature in your workspace, and the age of the battery all play a part. A battery in a busy warehouse might need more frequent top-ups compared to one in a less active environment. Keep an eye on these factors to gauge when it’s time for a refill.

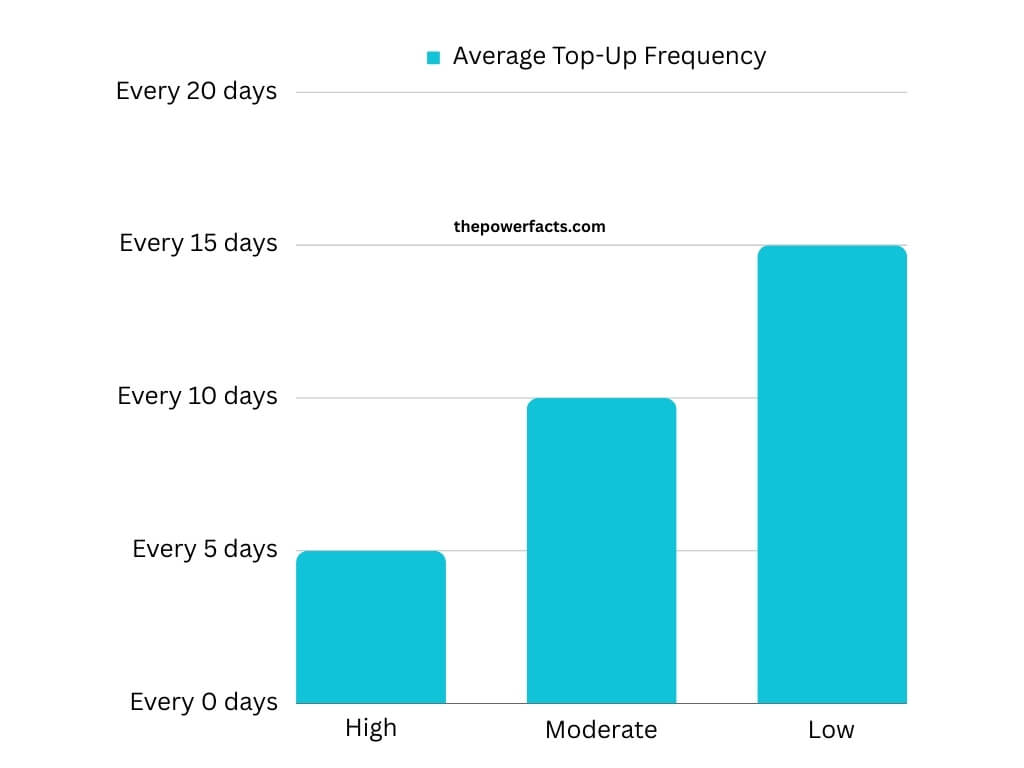

| Usage Level | Average Top-Up Frequency |

| High | Every 5 days |

| Moderate | Every 10 days |

| Low | Every 15 days |

This table gives you a rough idea of how often you should be checking your battery’s water level. Remember, these are just guidelines. Your battery might have its own unique thirst level!

Consequences of Improper Water Levels in Forklift Batteries

Risks of Overfilling and Underfilling

Messing up the water level in your forklift battery is like getting the wrong haircut; it’s not a good look, and it’s going to cause problems. Overfilling can lead to acid spills, damaging the battery and your forklift. Underfilling, on the other hand, shortens the battery’s life by exposing the internal plates. It’s all about finding that perfect level.

Signs of Water Level Issues

Keep an eye out for warning signs like slow performance or overheating. These could be your battery crying out for help. Regular checks and maintaining the right water level can save you from a lot of headaches down the road.

OSHA Guidelines for Forklift Battery Maintenance

Legal Requirements for Workplace Safety

OSHA isn’t just a bunch of rules; it’s there to keep you safe. When it comes to forklift batteries, OSHA has clear guidelines. They cover everything from proper handling to maintenance procedures. It’s not just about following the law; it’s about ensuring a safe work environment for you and your team.

Best Practices for Battery Handling and Maintenance

OSHA recommends regular maintenance, proper charging procedures, and using the right tools and equipment. It’s like taking care of a pet; you need to do it right to keep it healthy and happy. Following these guidelines not only keeps you on the right side of the law but also extends the life of your forklift battery.

FAQs

Can Weather Affect When to Add Water to a Forklift Battery?

Absolutely! Weather conditions play a significant role in your forklift battery’s water needs. In hot climates, water in the battery evaporates faster, necessitating more frequent top-ups. Conversely, in colder environments, water usage decreases, and so does the need for frequent refills. It’s essential to adjust your maintenance schedule according to the weather. During summer or in hotter working environments, keep a closer eye on the water levels. In winter, you can relax a bit but don’t forget to check periodically. This adjustment ensures your battery remains in optimal condition, regardless of the weather.

Is There a Risk of Battery Damage If Water Is Added Too Late?

Waiting too long to add water to your forklift battery can indeed be risky. If the water level drops too low, the exposed parts of the battery plates can sustain damage. This damage can lead to reduced battery capacity and a shorter overall lifespan. In severe cases, it might even cause the battery to fail completely. Regular checks are essential to prevent this. By keeping the water at the recommended level, you ensure the longevity and efficiency of your battery. It’s a simple step that can save you from costly repairs or replacements in the long run.

What Are the Signs of Low Water Levels in a Forklift Battery?

Identifying low water levels in a forklift battery is key to timely maintenance. Some signs include decreased performance and longer charging times. If the battery seems to be struggling or taking longer than usual to charge, it’s time for a check. Visually inspecting the battery cells can also reveal low water levels; if the tops of the internal plates are exposed, it’s a clear indication that water needs to be added. Regular monitoring helps in catching these signs early, preventing damage and maintaining optimal battery performance.

Does the Age of the Forklift Battery Affect Water Consumption?

Yes, the age of a forklift battery can influence its water consumption. As batteries age, they tend to require more frequent water top-ups. This is due to the natural degradation of battery cells over time, which affects their efficiency and water retention. Older batteries might also have less effective sealing, leading to quicker water evaporation. It’s important to adjust your maintenance routine as your battery ages, keeping a closer eye on older batteries to ensure they’re properly hydrated and functioning well.

Can the Type of Forklift Affect How Often Water Should Be Added?

The type of forklift you use can indeed impact how often you need to add water to the battery. Different forklift models have varying power requirements and battery sizes. A high-power forklift used in demanding conditions may consume battery water faster than a smaller, less intensive model.

The specific needs of your forklift’s battery and adjust the water top-up schedule accordingly. Regularly consulting the manufacturer’s guidelines can provide a clearer understanding of these requirements.

Is It Safe to Use Automated Watering Systems for Forklift Batteries?

Using automated watering systems for forklift batteries can be a safe and efficient way to maintain optimal water levels. These systems are designed to add the right amount of water at the correct time, reducing the risks of human error, such as overfilling or underfilling. They can be particularly useful in large operations where manual checking of each battery is time-consuming.

It’s still important to periodically inspect the system and the batteries to ensure everything is functioning correctly. Automated systems can greatly simplify maintenance, but they don’t entirely replace the need for occasional manual checks.

How Does Improper Water Addition Impact the Warranty of a Forklift Battery?

Improper water addition can have a significant impact on the warranty of your forklift battery. Most manufacturers specify maintenance guidelines, including how and when to add water. Failing to follow these guidelines can lead to battery damage, which might not be covered under warranty. It’s crucial to adhere to the recommended maintenance procedures to keep your warranty valid. This includes using the right type of water, adding it at the correct time, and avoiding overfilling or underfilling. Keeping a record of your maintenance routine can also be helpful in case of warranty claims.

So, there you have it! Taking care of your forklift battery isn’t just about adding water. It’s about doing it at the right time, using the right water, and following the right procedures. Keep these tips in mind, and your forklift battery will thank you with a long and productive life. Stay safe, and keep those batteries topped up!