Published on: October 29, 2022

Written by Jonas Frank / Fact-checked by Nova Scarlett

There are many different things that the acronym “PMS” can mean, but in the world of electrical engineering, it generally refers to power management systems. Power management systems are designed to help regulate the flow of electricity in a given area and can be used for commercial and residential purposes. In most cases, power management systems help save energy and money by reducing the amount of electricity wasted.

Regarding electrical engineering, the term “PMS” refers to power management systems. Power management systems ensure that an electrical system has enough power to run efficiently and safely. An electrical system can become overloaded and dangerous without a properly functioning power management system.

What is Electrical Power Management System?

An electrical power management system (EPMS) is a system that manages the flow of electricity in a building or other facility. It is responsible for distributing power to the various loads in the facility and monitoring and controlling the electricity consumption by those loads. The EPMS may also provide backup power if the primary power source fails.

The EPMS typically consists of four major components:

| Distribution panel | This is where electricity from the utility company enters the facility and is distributed to the various loads. The distribution panel includes circuit breakers or fuses that protect the wiring and devices connected to each circuit from overloads. |

| Local control device | These devices turn loads on or off or regulate their electricity consumption. They may be manually operated or controlled by an automated system that responds to changes in demand or prices for electricity. |

| Monitoring and controlling equipment | This equipment monitors the status of the distribution panel and load control devices and provides information about electrical usage within the facility to operators or managers. It may also include automatic controls that respond to conditions such as overloads or failures in system parts, shutting down affected circuits, or initiating an emergency generator start-up sequence. |

| Emergency backup power | In case of a loss of utility power, an emergency backup power source, such as a generator, can provide temporary power until the utility service is restored. |

5 Functions of Power Management Operation

Power management is a critical function in any organization. It ensures that electrical equipment and devices are operated safely and efficiently.

Here are 5 critical functions of power management operation:

| Load shedding | Load shedding refers to the controlled shutdown of non-essential equipment or devices to reduce overall power demand. Load shedding is often used during periods of peak power demand or when there is a risk of grid overload. |

| Peak shaving | This involves reducing power consumption during periods of high demand, typically by using less energy-intensive equipment or appliances. By lowering peak demand, organizations can avoid paying higher electricity rates and help reduce strain on the grid. |

| Voltage regulation | Power fluctuations can damage sensitive electronic equipment. Voltage regulators stabilize voltage levels, helping to protect against damage and ensuring the reliable operation of equipment. |

| Power factor correction | A low power factor can result in increased energy costs and decreased efficiency. Power factor correction helps improve the efficiency of electrical systems by correcting the phase angle between voltage and current waveforms. |

| Harmonic mitigation | Harmonics are undesirable voltages and currents that can cause problems with electrical equipment operation. Harmonic mitigation techniques help to reduce or eliminate harmonic distortion, improving system performance and reliability. |

What is Power Management System in Computer?

A power management system is a feature of some computer systems that allow the user to control the amount of power the system uses. The most common use for this is to reduce the power consumption of a system when it is not in use or when only low-power devices are needed, such as during battery operation. The ability to control the power consumption of individual components or groups of components can be used to improve system performance or battery life. Click here to read more about improving battery life.

For example, reducing the CPU clock speed and voltage when the system is idle can save significant power, as can turning off unused peripherals. Some systems also allow dynamic adjustment of these settings based on workload, so maximum performance is available when needed, but energy savings are still achieved when possible. In addition to saving energy, power management can also help to protect electronic components from damage caused by excessive heat or current.

By keeping component temperatures low, overall reliability is increased, and life expectancy can be extended.

What is a Power Management System?

A power management system (PMS) is a system that helps manage the power consumption of devices connected to a network. It can be used to turn off devices when they are not in use automatically or to schedule when devices should be turned on or off. PMSs can also provide information about device power usage and help reduce a network’s overall energy consumption.

Electrical Power Management System

An electrical power management system (EPMS) is a system that helps manage the use of electricity in a facility. It can be used to control the distribution of electricity, monitor usage, and provide information about the status of the electrical system. EPMSs are used in various settings, including commercial buildings, industrial facilities, and schools.

In a commercial setting, an EPMS can be used to monitor electricity usage and help reduce costs. The system can track how much electricity is being used by each tenant or department and identify areas where usage could be reduced. In an industrial setting, an EPMS can help optimize production by managing the electric load on the factory floor.

And in a school setting, an EPMS can help ensure that classrooms have adequate power for technology needs while reducing energy costs.

An EPMS typically includes three components: sensors, controllers, and displays:

- Sensors are installed throughout the facility and measure things like voltage, current, and power factor.

- Controllers use this information to adjust the flow of electricity based on demand automatically.

- Displays provide information about the status of the electrical system and can be used to override the system, if necessary, manually.

When choosing an EPMS for your facility, selecting one compatible with your existing electrical infrastructure that meets your specific needs is essential.

Be sure to work with a qualified installer who can properly configure the system for your application.

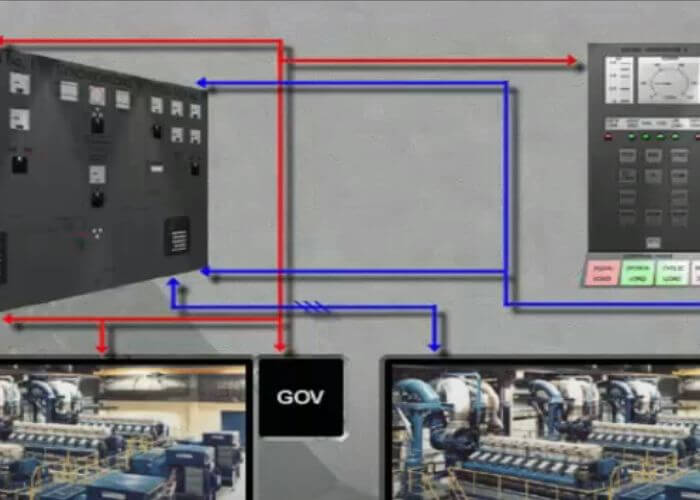

Power Management System in Ship

A power management system (PMS) is a computerized system used on ships to monitor and control the ship’s electrical power generation, distribution, and consumption. The PMS may be integrated with other computerized systems on the ship, such as the engine control system (ECS), navigation system, and safety management system. The primary purpose of a PMS is to ensure that the ship has an adequate supply of electrical power at all times and to prevent the overloading of the ship’s electrical circuits.

The PMS also monitors and records data about the ship’s electrical usage, which can be used for energy-efficiency purposes.

There are two power systems on ships: alternating current (AC) and direct current (DC). AC power is generated by diesel generators or gas turbines, while DC power is generated by batteries or fuel cells.

Most ships have both AC and DC power systems; however, some smaller vessels may only have one or the other. The PMS consists of several components: sensors, meters, controllers, relays, breakers, and displays.

- Sensors detect various parameters of the ship’s electrical system, such as voltage, current, frequency, and power factor.

- Meters are used to measure these parameters.

- Controllers compare the measured values with preset values and activate or deactivate specific devices to maintain safe operating conditions.

- Relays are used to switch devices on or off remotely.

- Breakers are used to disconnect circuits automatically in case of an overload or short circuit.

Power Management System Function

A power management system’s function is to provide safe, reliable, and efficient electric grid operation.

The power management system has three main functions:

Load Control

The load control function manages the grid’s electricity demand by regulating how much power is used at any given time. This helps to prevent blackouts and brownouts by managing the flow of electricity so that it meets the needs of everyone on the grid.

Voltage Regulation

The voltage regulation function keeps the voltage consistent throughout the electric grid. This helps prevent equipment damage and ensures that customers receive quality service.

Frequency Regulation

The frequency regulation function keeps the frequency of electricity at a consistent level. This helps to prevent problems with equipment and provides customers with quality service.

DC Power Management System

A DC power management system is a critical component of any solar PV system. It is responsible for ensuring that the solar panels can produce enough electricity to meet the home or business’s needs and storing excess electricity for use during periods of low sunlight. The DC power management system consists of the solar controller, the battery bank, and the inverter.

The solar controller is responsible for regulating the flow of electricity from the solar panels to the batteries. The batteries store excess electricity for use during periods of low sunlight. The inverter converts DC electricity into AC electricity, which household appliances can use.

Solar PV systems are becoming increasingly popular for generating renewable energy. A DC power management system is essential to any solar PV system. It helps to ensure that the solar panels can generate enough electricity to meet the home or business’s needs.

Why is Power Management System Important?

Electricity is one of the essential things in our daily lives. It powers our lights, appliances, and electronic devices. But it can also be dangerous.

That’s why power management systems are so important. Power management systems help regulate electricity flow in a home or business. They keep electrical currents from getting too high or low and protect against power surges.

Power management systems are essential for safe electrical use and can even help save energy. There are two main types of power management systems: circuit breakers and fuses. Circuit breakers are found in most homes and businesses today.

They trip when an electric current becomes too strong, protecting wires and devices from damage. Fuses are older technology but are still used in some applications. They work by melting when an electric current becomes too strong, breaking the circuit and stopping the flow of electricity.

Both circuit breakers and fuses are essential parts of any power management system. They both provide safety and protection against electrical hazards. And they both can help save energy by regulating the flow of electricity in a home or business.

What is PMS Electrical?

PMS electrical is an abbreviation for preventive maintenance schedule. It is a plan that helps an organization keep track of its equipment and machinery to avoid costly repairs or replacements. By regularly inspecting and servicing equipment, PMS electrical can help reduce the risk of breakdowns and improve the lifespan of machinery.

In addition, PMS electrical can also improve safety in the workplace by ensuring that all equipment is operating correctly.

What is PMS in Substation?

PMS is a power management system for substations. It monitors, controls, and optimizes the performance of substation equipment and systems. PMS helps to ensure the safe, reliable, and efficient operation of substations.

What is the Meaning of Power Management?

Power management regulates the electrical power supply to an electronic device or system. Its primary purpose is to conserve energy and reduce costs by turning off unused devices or reducing their power consumption. Power management can also refer to managing and efficiently distributing energy resources.

End Note

PMS is an acronym that stands for “Power Management System.” It is a system that helps regulate the power usage of devices connected to a central power source. The purpose of PMS is to save energy and reduce costs by managing the power consumption of devices connected to the system.

Used Resources: