A Battery Management Controller (BMC) is an electronic device that manages a rechargeable battery system. The BMC performs several critical functions, including monitoring the battery pack’s voltage, current, and temperature; balancing the cell voltages; and providing over-voltage, over-current, and over-temperature protection. A good BMC will also offer features like cell balancing, data logging, and firmware updates.

A battery management controller (BMC) is a device that manages the charging and discharging of batteries. It regulates the voltage and current going into and out of the battery to protect it from overcharging or over-discharging. The BMC also monitors the temperature of the battery to prevent it from overheating.

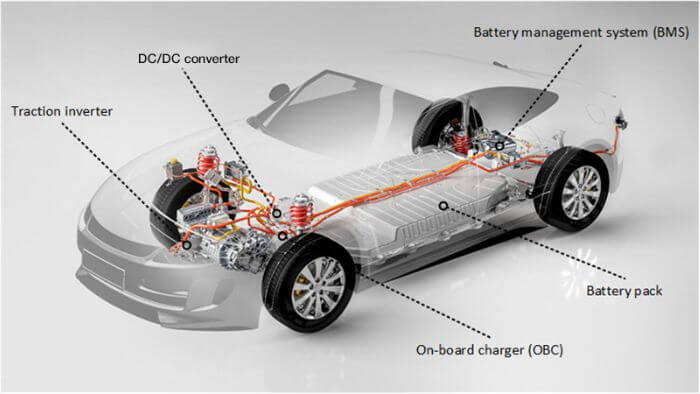

What is Battery Management System for Electric Vehicles?

The Battery Management System is a critical component in any electric vehicle. Its primary purpose is to ensure that the battery pack stays within its operating limits, providing optimal performance and longevity. The system does this by constantly monitoring the cell voltages and temperatures, as well as the current flowing in and out of the pack.

It then uses this information to adjust the amount of power being drawn from the cells, balancing the load to prevent any one cell from being over-stressed. In addition to managing the power flow, the BMS also protects the cells from damage due to over-charging or over-discharging. It will shut off power to the pack if it detects that any of these conditions are met, preventing permanent damage to the cells.

Without a properly functioning BMS, an electric vehicle would be at risk of catastrophic failure due to battery misuse. That’s why it’s so important that this system is always working correctly, and why regular maintenance is essential for keeping your EV on the road.

Disadvantages of Battery Management System

The disadvantages of battery management system are as follow:

1. There is a decrease in the overall efficiency of the system.

2. The maintenance cost for BMS is high when compared to other systems.

3. BMS also decreases the capacity and power output of batteries.

Battery Management System 18650

As the world increasingly moves toward electrification, the need for efficient and reliable battery management systems (BMS) is more important than ever. The 18650 battery is a popular choice for many applications, including electric vehicles, due to its high energy density and reliability. A good BMS will help to ensure that your 18650 batteries are properly charged and discharged, while also protecting them from over-voltage, over-current, and thermal runaway.

In this blog post, we’ll take a look at what you should look for in a BMS for your 18650 batteries. When choosing a BMS for your 18650 batteries, there are several things to consider:

1. Voltage and Current Rating

The voltage of your BMS should be equal to or greater than the nominal voltage of your batteries (3.6V for most 18650 cells).

The current rating should be high enough to handle the maximum discharge current of your application. For example, if you’re using 18650 cells in an electric vehicle with a maximum discharge current of 30A, you’ll need a BMS with a minimum current rating of 30A.

2. Balance Function

A good BMS will have some form of balance function to ensure that all of the cells in your pack are evenly charged and discharged.

This helps to prevent capacity loss and extends the life of your batteries.

3. Over-Voltage Protection

This protects your cells from being overcharged, which can damage them irreparably. Make sure that the BMS you choose has adjustable over-voltage protection settings so that you can set it according to the needs of your application.

4. Over-Current Protection

This protects your cells from being discharged at too high of a rate, which can also damage them irreparably. Again, make sure that the B MS you choose has adjustable over-current protection settings so that you can set it according to the needs of y our application.

Types of Battery Management System

A battery management system (BMS) is a device that monitors and manages the charging and discharging of batteries. It ensures that the batteries are used safely and efficiently, and extends their lifespan. BMSs are used in a variety of applications, including electric vehicles, power tools, UPS systems, and solar energy storage systems.

They typically consist of a control unit, sensors, and actuators. The control unit uses algorithms to optimize the performance of the batteries based on information from the sensors. The actuators may be used to disconnect the load from the batteries when necessary.

The most important function of a BMS is to protect the batteries from overcharging or deep discharge. Overcharging can damage the battery cells and shorten their lifespan. Deep discharge can also damage cells, but it can also lead to safety hazards such as thermal runaways if not properly managed.

BMSs typically include features such as cell balancing, which equalizes charge across all cells in a pack; temperature monitoring; voltage monitoring; current monitoring; and communication with an external charger or grid-tie inverter. Some BMSs also have self-diagnostic capabilities that can detect problems with individual cells or other components of the system.

Battery Management System Requirements

A battery management system (BMS) is a critical component in any application where Lithium-ion batteries are used. The BMS is responsible for ensuring the safe and reliable operation of the battery pack, by monitoring and managing the individual cells within the pack in real time. There are many different types of BMS on the market, each with its own set of features and capabilities.

When choosing a BMS for your application, it is important to consider the specific requirements of your application in order to select a BMS that is best suited for your needs. Some common requirements that should be considered when selecting a BMS include:

| Cell balancing | Balancing refers to equalizing the charge between cells in order to prevent overcharging or undercharging of individual cells. This is typically accomplished by periodically distributing charge from higher-capacity cells to lower-capacity cells until all cells reach their full charge potential. Most Lithium-ion batteries require periodic cell balancing in order to operate at peak performance and longevity. |

| Temperature monitoring | It is important to monitor the temperature of both the battery pack and its environment as extreme temperatures can lead to safety hazards or decreased performance. Some BMS systems include built-in temperature sensors while others require external sensors to be installed in order to monitor the temperature. |

| Charge/discharge control | The BMS must be able to safely control both the charging and discharging of the battery pack according to user-defined parameters such as voltage, current, and time limits. |

| Data logging | A good BMS will have the ability to log data related to battery performance and health over time. This data can be used for analysis and trending purposes in order help optimize battery usage and predict future failures. |

Battery Management Software

Most people think of battery management as something that only applies to large companies with complex electrical systems. However, any business or individual that uses batteries can benefit from using battery management software (BMS). A BMS is a computer application that helps you monitor and optimize your use of batteries.

It can provide information about the health of your batteries, how much charge they have left, and when they need to be replaced. Additionally, a BMS can help you maximize the efficiency of your charging system and prevent overcharging or damage to your batteries. If you are responsible for managing a fleet of vehicles or other equipment that uses batteries, a BMS can save you time and money by helping you keep track of your assets and ensuring that they are operating at peak efficiency.

In addition, many BMS applications offer features such as remote monitoring and reporting, which can give you peace of mind knowing that your equipment is being monitored even when you are not on site. Whether you are managing a few batteries or an entire fleet, battery management software can help you extend the life of your batteries and save money in the long run.

Battery Management System Design

Designing a Battery Management System (BMS) can be a daunting task. There are many factors to consider, from the type of batteries you are using to the way in which you want to manage them. In this blog post, we will take a look at some of the key considerations for designing a BMS, so that you can make an informed decision about what is right for your needs.

The first thing to consider when designing a BMS is the type of batteries you are using. Li-ion batteries are a popular choice for many applications, but they require a different management strategy than lead-acid batteries. Make sure you understand the differences between these battery types before making any decisions about your BMS design.

Next, think about how you want to manage your batteries. There are two main approaches: active management and passive management. Active management systems actively monitor each individual cell in the battery pack and provide voltage and current regulation to keep them within safe operating limits.

Passive management systems do not monitor or regulate individual cells but instead, focus on providing information about the overall state of charge of the pack. Which approach is best for your application will depend on your specific needs. Once you have considered these key points, it is time to start thinking about the details of your BMS design.

This includes everything from selecting the right components to writing firmware that will control how the system behaves. If you need help with any aspect of this process, there are plenty of experts out there who can offer guidance and support – so don’t be afraid to ask for help!

Is a Battery Management System Necessary?

Most battery management systems (BMS) are designed to protect the battery pack from operating outside its safe limits. The BMS does this by monitoring the voltage, current, and temperature of each cell in the pack and balancin$

A BMS is not strictly necessary for a battery pack, but it is highly recommended.

Without a BMS, the only way to know if a cell is getting too hot or taking on too much current is to measure it directly.

What Does a Battery Management System Consist Of?

A battery management system (BMS) is a circuit that monitors and regulates the charging and discharging of batteries. It protects batteries from overcharging and over-discharging, which can shorten their lifespan. A BMS also balances the cells in a battery pack, so that they all have the same voltage.

This prevents one cell from becoming overloaded while another cell is undercharged, which can damage the battery pack. Most BMSs are made up of three main components: a microcontroller, sensors, and MOSFETs (metal-oxide-semiconductor field-effect transistors). The microcontroller constantly monitors the voltages of the individual cells in a battery pack using the sensors.

When it detects that one cell is becoming too low or too high, it uses the MOSFETs to redirect charge to or from that cell, balancing out the voltages. BMSs are an essential component of any lithium-ion battery pack. Without one, your battery could be damaged by overcharging or over-discharging.

If you’re using lithium-ion batteries in your project, make sure to include a BMS!

What is Battery Management System in a Vehicle?

A battery management system (BMS) is a critical component in any electrical vehicle. Its primary purpose is to protect the battery pack from operating outside its safe limits, and to ensure that the pack delivers its full rated capacity and power. The BMS constantly monitors the battery pack’s voltage, current, temperature and health status.

If any of these parameters exceed their safe limits, the BMS will take appropriate action to protect the battery pack. For example, if the pack’s voltage gets too high, the BMS will disconnect it from the rest of the vehicle’s electrical system to prevent damage. The BMS also has a balancing function that keeps all of the cells in the battery pack at an equal state of charge.

This ensures that each cell is used equally over time, which maximizes the pack’s overall lifespan. Finally, the BMS typically provides diagnostic information about the battery pack that can be used by technicians to troubleshoot problems or optimize performance.

Do All Lithium Batteries Have a BMS?

No, not all lithium batteries have a BMS. A BMS is a battery management system, which is used to protect the battery from overcharging, over-discharging, and excessive current. It is not required for all applications, but it is recommended for safety and longevity of the battery.

In a Nutshell

A battery management controller (BMC) is a device in conjunction with a solar panel or wind turbine to store energy for later use. The BMC can be used to monitor the status of the battery, control the charging and discharging process, and protect the battery from over-charging or over-discharging.