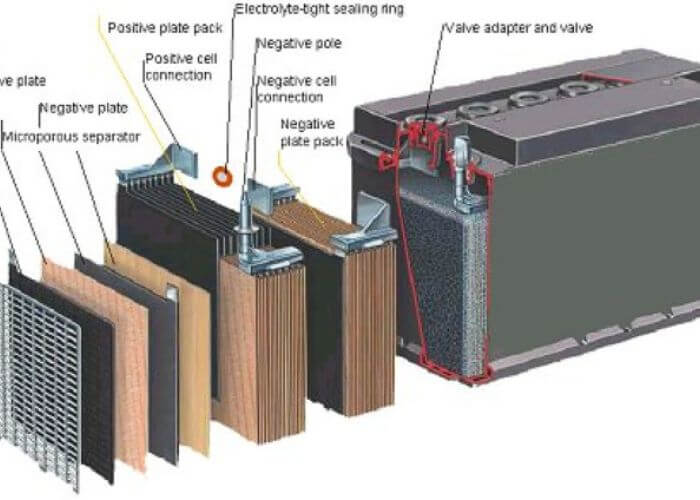

Lead acid batteries have more negative plates than positive plates for several reasons. The most common lead acid battery is the flooded lead acid battery, which has two cells with three compartments each. The center compartment is the neutral plate and the outer compartments are the positive and negative plates.

The positive plate contains a larger surface area of lead oxide than the negative plate, so it needs more space. In addition, the positive plate produces hydrogen gas during charging, so it must be vented to prevent pressure build-up.

Lead acid batteries are one of the most popular types of batteries on the market today. They are used in a variety of applications, from cars to boats to golf carts. One of the reasons lead acid batteries are so popular is because they are very efficient at storing and releasing energy.

Another reason lead acid batteries are so popular is because they have more negative plates than positive plates. This gives them a higher voltage potential than other battery types, which means they can store and release more energy. The downside to having more negative plates than positive plates is that lead acid batteries tend to be heavier and bulkier than other battery types.

They also require more maintenance, as the extra negative plates need to be regularly cleaned and replaced.

How the Number of Positive And Negative Plates are Compared in a Lead Acid Battery?

A lead acid battery typically has twice as many negative plates as positive plates. The number of plates can vary depending on the size and type of battery, but the ratio is usually 2:1. This imbalance is necessary to maintain charge neutrality and prevent the formation of dendrites, which can short out the battery.

Which Plate is More in Lead Acid Battery?

When it comes to lead acid batteries, there is no one “right” answer for which plate is more in lead. However, the most common lead acid battery used in cars and trucks has a positive plate made of lead dioxide and a negative plate made of sponge lead. The reason for this is that the lead dioxide can better withstand the repeated charging and discharging cycles that occur in automotive applications. Lead acid battery take a long time to charge.

Which Plate is More in Battery?

If you’re talking about a car battery, the positive plate is usually more in “battery” than the negative plate. The negative plate typically has more sulfate build-up on it, which can reduce its effectiveness.

How Many Negative Plates Does a Lead Acid Battery Have?

A lead acid battery has two negative plates. The number of positive plates varies depending on the battery’s size and capacity.

People Also Asked

What is the Function of Charging System?

A car’s charging system is responsible for supplying power to the battery and electrical components of the vehicle. The charging system includes an alternator, which is powered by the engine, and a voltage regulator. The alternator produces electricity that is used to charge the battery and power the electrical components.

The voltage regulator controls the amount of electricity produced by the alternator so that it doesn’t damage the battery or electrical components.

What is a Wet Battery?

A wet battery is a type of lead-acid battery that uses a liquid electrolyte instead of the more common solid or gel electrolytes. The advantage to using a wet battery is that it can be made smaller and lighter than other types of batteries. Wet batteries are also less likely to leak, making them safer to use.

How Should Customers Store Batteries in the off Season?

Assuming you’re talking about lead-acid batteries. Batteries should be stored in a cool, dry place. The ideal temperature is between 50 and 70 degrees Fahrenheit.

Batteries should be charged to about 75 percent of their capacity before being stored. This will help prevent sulfate, which can damage the battery and shorten its lifespan. If possible, it’s also a good idea to store batteries on a concrete floor rather than on wood or carpeting.

This will help protect them from fire if they happen to leak.

What is Buckling Action?

Buckling is a mode of failure for slender structures. It can occur due to different types of loading, but is most commonly associated with compression. When a structure buckles, it experiences an instability that causes it to deform or collapse.

There are two main types of buckling: local and global. Local buckling occurs when small sections of the structure deform. This can happen if the material is not strong enough to resist the applied load, or if the section is too thin.

Global buckling happens when the entire structure deforms. This usually happens when the load on the structure is too great, or when the structure is not supported properly.

Buckling can be prevented by using stronger materials, increasing the thickness of structural members, or providing additional support.

Converting Chemical Energy to Electrical Energy

Converting chemical energy to electrical energy is a process that can be used to generate power. There are a few different ways to convert chemical energy into electricity, but the most common method is through combustion. In this process, fuel is burned in an engine to create heat, which is then used to turn a generator and create electricity.

Other methods of converting chemical energy into electricity include electrochemical reactions (such as those that occur in batteries), and thermoelectric generators (which use the difference in temperature between two objects to create a current). Chemical energy can also be converted into mechanical energy, which can then be used to power electric motors or other devices. conversion of chemical energy into electrical energy is not 100% efficient, so some of the potential power is lost during the process.

However, it is still a very effective way to generate electricity, and has many applications in both industry and homes.

Sponge Lead

Sponge lead is a type of lead used in the production of leaded glass. It is made from processing lead ore into a fine powder, then adding it to molten glass. The resulting glass has a high lead content and is very dense.

Sponge lead is also used as a radiation shielding material and as an additive to paint and enamel to increase durability.

AGM Battery

An AGM battery is a lead-acid battery that uses an absorbed glass mat (AGM) separator between the positive and negative plates. The AGM separator absorbs and contains the electrolyte, eliminating the possibility of spillage and providing a microfiber route for electrical current that results in a very low internal resistance. This makes them ideal for use in high-performance vehicles and other applications where weight and space are at a premium.

AGM batteries were originally developed for military aircraft, where their superior performance was critical to safety. Today, they are used in a wide range of applications including race cars, motorcycles, UPS systems, wheelchairs, and more. Many people believe that AGM batteries can use a lead acid battery as a replacement. lead-acid batteries available on the market today.

There are several advantages to using an AGM battery over a traditional lead-acid battery:

| Point it | Advantages for AGM Batteries |

| 1 | They can be discharged deeper without damage up to 100% compared to 50% for traditional lead-acid batteries. |

| 2 | They have much lower self-discharge rates. So they will stay charged longer when not in use. |

| 3 | They can be used in any orientation. So they can be installed in tight spaces where other types of batteries would not fit. |

Conclusion

Lead acid batteries have more negative plates than positive due to the way they are made. The negative plates are made of lead oxide, while the positive plates are made of pure lead. The lead oxide is heavier than the lead, so it takes up more space on the plate.

That’s why there are more negative plates in a lead acid battery.