To power a 3kVA inverter, you would typically need two 200Ah batteries. This setup ensures efficient operation and adequate backup power.

Selecting the right number of batteries for an inverter is a key decision in setting up a reliable power system. For a 5kVA inverter, the requirement often increases to four 200Ah batteries, especially if the goal is to maintain a consistent power supply. The capacity of a 200Ah battery to power a home varies based on the total energy consumption. However, in a standard setup, a couple of these batteries can efficiently run essential home appliances.

When considering a 5kVA 48V inverter, the battery requirement changes. Typically, four 12V 200Ah batteries connected in series are ideal to meet the voltage requirements while providing sufficient backup. The duration a 200Ah battery can run a fridge or other appliances depends on the power consumption of the appliance. For instance, a 200Ah battery can typically run a fridge for about 24 hours, depending on the fridge’s energy efficiency.

For a specific load, like running a 3.2 kW load for 14 hours, calculating the total energy requirement helps in determining the number of batteries needed. In this case, you would need a substantial battery bank, possibly involving multiple 200Ah batteries, to sustain this load for the specified duration.

The lifespan of a 200Ah battery is another critical factor. Generally, these batteries last between 3 to 5 years, but this can vary based on usage patterns and maintenance. The size of the inverter also influences the choice of battery. A 200Ah battery is well-suited for inverters up to 3kVA, but larger systems may require more or larger batteries.

For a detailed understanding of how many batteries you need for different inverter sizes and loads, including a 5kVA inverter, and insights into optimizing your battery and inverter setup, read the detailed article below.

How Many 200Ah Batteries for 3kVA Inverter?

Battery Requirements for 3kVA Inverters

Basics of Inverter and Battery Compatibility

When it comes to powering a 3kVA inverter, choosing the right battery is like picking a dance partner – it needs to be a perfect match. The inverter and battery must work in harmony to ensure efficient power delivery. The capacity of the battery, measured in ampere-hours (Ah), determines how long it can supply power. For a 3kVA inverter, a 200Ah battery is often a popular choice, balancing capacity with practicality.

Key Factors Influencing Battery Selection

Selecting a battery isn’t just about the numbers; it’s about understanding your power needs. You need to consider the load, the duration of power supply required, and the environment where the inverter will be used. For instance, a home setup might have different requirements compared to a small business. It’s all about tailoring the battery choice to fit your specific situation.

Calculating Battery Needs for 3kVA Inverters

Step-by-Step Guide to Calculating Battery Capacity

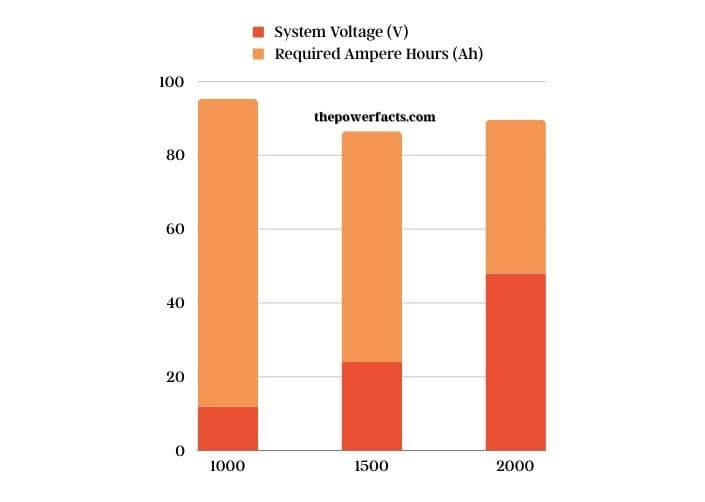

Let’s break down the math. To figure out how many batteries you need, start by calculating the total power requirement of your appliances. This is measured in watts. Then, consider the voltage of your system, usually 12V, 24V, or 48V. The formula is simple: Total Power Requirement (in watts) / System Voltage = Required Ampere Hours. This calculation gives you a clear picture of your battery needs.

Battery Capacity Calculation Examples

| Appliance Power (Watts) | System Voltage (V) | Required Ampere Hours (Ah) |

| 1000 | 12 | 83.33 |

| 1500 | 24 | 62.5 |

| 2000 | 48 | 41.67 |

Optimal Battery Configuration for 3kVA Inverters

Series vs. Parallel Configurations

Configuring your batteries correctly is crucial. In a series setup, the voltage increases while the capacity (Ah) remains the same. In contrast, a parallel configuration keeps the voltage constant but increases capacity. For a 3kVA inverter, you might opt for a series setup if you’re using a higher voltage system or parallel if you need more capacity at a lower voltage.

Best Practices in Battery Configuration

It’s not just about connecting batteries; it’s about doing it right. Ensure all batteries have the same capacity and are in good condition. Uneven batteries can lead to inefficiencies and even damage. Regular checks and balances are key to maintaining an optimal setup.

Battery Lifespan and Maintenance

Average Lifespan of 200Ah Batteries

On average, a 200Ah battery will serve you well for about 3 to 5 years. But this isn’t set in stone. The lifespan can vary based on how you use and maintain the battery. Think of it like a car; regular maintenance can significantly extend its life.

Maintenance Tips to Prolong Battery Life

Keeping your batteries in top shape involves regular cleaning, ensuring they’re properly charged, and avoiding overuse. It’s like taking care of a pet – regular attention and care go a long way.

Maintenance Schedule and Checklist

| Maintenance Task | Frequency | Notes |

| Visual Inspection | Monthly | Check for damages or leaks |

| Terminal Cleaning | Bi-Monthly | Remove corrosion |

| Voltage Check | Monthly | Ensure consistent voltage |

| Full Recharge | After Every Use | Avoid partial recharges |

Real-World Applications and Case Studies

Case Study: Residential Use of 3kVA Inverter with 200Ah Batteries

In a typical home scenario, a family used a 3kVA inverter with two 200Ah batteries. This setup efficiently powered their essential appliances during outages, including lights, a fridge, and a TV. The key was balancing their power usage with the capacity of their batteries.

Case Study: Commercial Applications

A small business owner implemented a similar setup but with additional batteries to handle a higher load. This not only provided uninterrupted power but also ensured the longevity of the batteries due to the distributed load.

Advanced Considerations and Upgrades

Upgrading from 200Ah Batteries: Pros and Cons

Thinking of upgrading? Larger batteries can offer more power but come with increased costs and space requirements. It’s a trade-off between capacity and practicality.

Future-Proofing Your Inverter and Battery Setup

Investing in quality batteries and considering future power needs can save you from frequent upgrades. It’s like planting a tree; planning for the future yields long-term benefits.

Comparison of Battery Types and Their Suitability

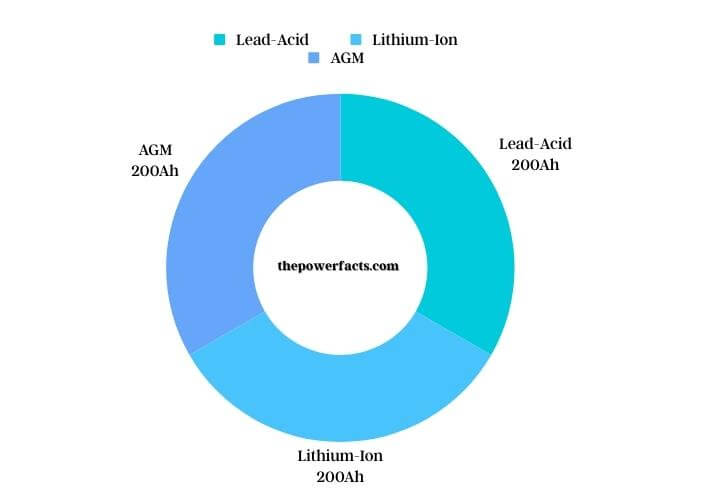

| Battery Type | Capacity | Suitability for 3kVA Inverter | Notes |

| Lead-Acid | 200Ah | High | Cost-effective, widely available |

| Lithium-Ion | 200Ah | Moderate | More expensive, longer lifespan |

| AGM | 200Ah | Moderate | Maintenance-free, less durable |

FAQs

Can Different Brands of 200Ah Batteries Be Mixed for a 3kVA Inverter?

Mixing different brands of 200Ah batteries for a 3kVA inverter is not recommended. Even if the batteries are of the same capacity, variations in manufacturing processes can lead to differences in performance characteristics. This mismatch can result in uneven charging and discharging, reducing the overall efficiency and lifespan of your battery setup. It’s similar to running a relay race with athletes of different speeds; the team’s performance is compromised. For optimal performance and longevity, it’s best to use batteries of the same brand, model, and age.

What Is the Impact of Temperature on 200Ah Batteries for a 3kVA Inverter?

Temperature plays a significant role in the performance of 200Ah batteries used with a 3kVA inverter. Extreme temperatures, both hot and cold, can affect the battery’s ability to hold and deliver charge. In high temperatures, batteries may overheat, leading to accelerated degradation and reduced lifespan. In contrast, cold temperatures can decrease the battery’s capacity and its ability to deliver power effectively. It’s like trying to operate in extreme conditions; performance inevitably suffers. To maintain battery efficiency, it’s crucial to store and operate them in a temperature-controlled environment.

What is the Best Battery Setup for Maximizing Battery Life with 1000W Inverters?

When determining the best battery setup for maximizing battery life with 1000W inverters, it’s important to consider factors like the battery type, capacity, and voltage. Additionally, using efficient energy management strategies and deep cycling batteries can be effective in extending battery life and optimizing performance.

Is It Necessary to Use a Battery Management System (BMS) with 200Ah Batteries?

Using a Battery Management System (BMS) with 200Ah batteries for a 3kVA inverter is highly beneficial. A BMS monitors and manages the battery’s operation, ensuring each cell within the battery is charged and discharged correctly. This system helps in prolonging the battery’s life, preventing overcharging, deep discharging, and imbalances among cells. Think of it as having a personal trainer for your batteries, guiding and protecting them through their operational life. While not mandatory, a BMS is a valuable addition for maximizing battery efficiency and lifespan.

How Does the Depth of Discharge (DoD) Affect 200Ah Batteries?

The Depth of Discharge (DoD) significantly impacts the lifespan of 200Ah batteries used in a 3kVA inverter system. DoD refers to the percentage of the battery that has been discharged relative to its overall capacity. Regularly discharging the battery deeply (a high DoD) can shorten its lifespan. It’s akin to constantly running a car’s fuel tank close to empty; it stresses the system. Ideally, keeping the DoD to a moderate level, typically around 50%, can help in extending the battery’s life.

Can 200Ah Batteries Be Used in Both Off-Grid and On-Grid Systems?

Yes, 200Ah batteries can be used in both off-grid and on-grid systems with a 3kVA inverter. In off-grid systems, these batteries are the primary source of power storage, crucial for ensuring a continuous power supply. In on-grid systems, they serve as a backup, storing excess power generated, for instance, from solar panels, and providing power during outages. The versatility of 200Ah batteries makes them suitable for various setups, much like a multi-purpose tool in your toolkit.

What Are the Safety Precautions for Using 200Ah Batteries with a 3kVA Inverter?

Safety is paramount when using 200Ah batteries with a 3kVA inverter. Always install the batteries in a well-ventilated area to prevent the buildup of gases. Regularly check for any signs of damage or leaks, as these can lead to short circuits or fires. It’s also important to ensure that the batteries are securely mounted and that all connections are tight and corrosion-free. Think of it as setting up a safety net; it’s crucial for preventing accidents. Additionally, using protective gear when handling batteries is advisable to avoid accidents.

How Does the Charging Source Affect the Performance of 200Ah Batteries?

The charging source has a significant impact on the performance and lifespan of 200Ah batteries used with a 3kVA inverter. Using a high-quality charger that provides the correct voltage and current is essential. An inappropriate charger can lead to undercharging or overcharging, both of which can harm the batteries. Solar chargers, for instance, need proper regulation to ensure consistent and safe charging. It’s like fueling a vehicle; the quality and type of fuel matter greatly. Ensuring the right charging source is akin to providing the best possible fuel for your batteries’ long and efficient service life.

In conclusion, powering a 3kVA inverter with 200Ah batteries involves careful consideration of your power needs, the right configuration, and regular maintenance. Whether it’s for home or commercial use, understanding these aspects ensures a reliable and efficient power system. Remember, it’s not just about getting the biggest battery; it’s about getting the right battery for your needs.